Grinding of Cereals

The raw materials that will later be modified and transformed into a final product, must be ground to achieve the desired granulometry.

Weighing and Mixing Raw Materials

The ground raw materials together with the other ingredients are weighed and mixed in a continuous cycle, achieving the optimum homogenization of the mixture.

Doser and Pre-conditioner

Prior to entering the extruder, the mixture is treated with regulated flows of water and steam under pressure. The doser regulates the flow of entry to the extruder.

Extruder

The mixture enters the extruder where a thermophysical process is exposed, here the temperature and the pressure that allows to gelatinize starches and texture the proteins rise. The treated flour is sold at the end of the extruder through different matrices and a temperature of approximately 180 ° C. Finally the product is cut by blades that rotate at high revolutions giving, in this way, the required conformation.

Drying and Chilling

The semi-solid product is transported pneumatically to the drying equipment. In this stage, the product receives hot air currents in the first two sections and cold air in the final stage of cooling.

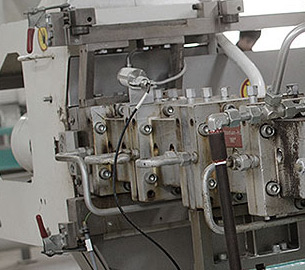

Adjustment of particle size

Through the passage through a bank of fluted cylinders or hammer mill, the controlled grinding of the product is carried out until reaching the desired granulometry.

Sifting

According to the customer's specifications, the product passes through different screens until a final product of homogeneous size is obtained.

Packing

It is done by an automatic fractionation system in bags of Kraft paper or Big Bags.